Dongguan Baoding Precision Instrument Co. Ltd.

Miss.Cai 13717346368

Telephone: 0769-85588096Fax: 0769-82688299

Email: 13717346368@163.com

URL: www.baodingyiqi.com

Address: No. nine Park Avenue, Houjie Town, Guangdong, Dongguan, China, No. 23

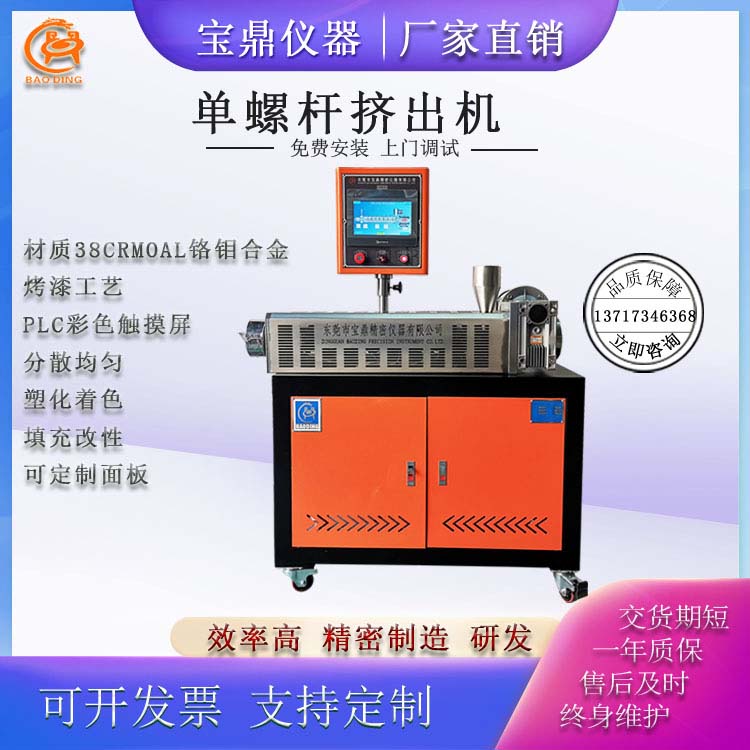

BD-8858-B小型单螺杆挤出机/程控型PLC

Introduction

BD-8858-B

Laboratory single screw extruder / PLC program controlled

It is suitable for mixing, plasticizing and extrusion of high molecular polymers such as engineering plastics, modified plastics and color masterbatch. It has the characteristics of uniform dispersion, plasticizing and coloring, filling and modification. It is suitable for laboratory test and quality control, teaching research and small-scale production.

BD-8858-B laboratory single screw extruder //PLC program-controlled

This machine is suitable for engineering plastics, modified plastics, masterbatch polymer plasticating and extrusion, has the characteristics of uniform dispersion, plastic coloring, filling modification etc.. Suitable for laboratory testing and control quality, teaching research and small-scale production.

1 screw diameter: 20, 25, 30 optional

2 screw speed: 0-80rpm variable frequency speed regulation

3 length diameter ratio: 25, other length diameter ratio (10~30 times) optional

4 screw material: 38CrMoAl chromium molybdenum alloy, surface quenched, nitride, chromium plating, polishing and ultra precision honing process, hardness HRC55~60, roughness Ra is less than or equal to 0.4 mu m, depth of reach more than 0.6mm

5 barrel material: 38CrMoAl chromium molybdenum alloy, surface quenched, nitrided, chrome plating, polishing and ultra precision honing process, hardness HRC55~60, roughness Ra is less than or equal to 0.4 mu m, depth of reach more than 0.6mm

6 heating zones: the barrel area 4 mica heater, heater head 1 District, each district with copper fins, covered with stainless steel safety cover

7 cooling device: 3 sets of multi wing fan static forced air cooling

8 drive motor: 0.75~2.2KW gear reducer motor

9 power supply: 3 MV, AC380V, 50Hz three-phase five wire

10 electrical control system: PLC programmable color touch screen, man-machine interface operating system, extrusion process can be dynamically displayed and monitored